Fault Tree Analysis Template

- Fault Tree Analysis Template Word

- Fault Tree Analysis Template Excel

- Fault Tree Analysis Template Excel

Fault Tree Analysis on R. An R package has been developed to build fault trees as traditionally used for risk analysis. Probabilistic Risk Assessment (PRA) and Reliability, Availability, and Maintainability (RAM) fault tree models are supported for related analyses.By our definition PRA models are often time dependent and are well suited for systems that cannot be repaired within a given.

Fault tree analysis diagrams are commonly used to illustrate events that might lead to a failure so the failure can be prevented. Fault tree analysis diagrams are commonly used in Six Sigma processes, particularly in the Analyze phase of the Six Sigma business improvements process.

You begin by defining the top event (or failure). Then you can use event and gate shapes to illustrate, top-down, the process that might lead to the failure. Once you complete the diagram, you can use it to identify ways to eliminate causes of the failure and to devise corrective measures for preventing such failures.

In Visio 2013 and newer versions: Start Visio, and click Business > Fault Tree Analysis Diagram > Create.

In Visio 2010: On the File menu, point to New, point to Business, and then click Fault Tree Analysis Diagram.

From Fault Tree Analysis Shapes, drag the Event shape to the top of the drawing page.

Drag a gate shape, such as the Exclusive OR gate, onto the drawing page directly below the first event shape.

Continue dragging other event and gate shapes onto the page, positioning them in top-down order to identify the potential causes of the failure represented by the top-level event shape.

Connect the shapes.

Drag a shape from a stencil onto the drawing page and position it near another shape.

While still holding down the mouse button, move the pointer over one of the blue triangles. The triangle turns dark blue.

Release the mouse button. The shape is placed on the drawing page, and a connector is added and glued to both shapes.

To add text to a shape, select it, and then type. When you are finished typing, click outside the text block.

Notes:

To edit text, double-click the shape, place the cursor where you want to change the text, and then type.

To hyperlink a shape to supporting or explanatory documents, select the shape, and then, on the Insert menu, click Hyperlinks.

To align multiple shapes vertically or horizontally, select the shapes you want to align, then, on the Home tab > Arrange group, click Align.

To distribute three or more shapes at regular intervals, select the shapes, and then, on the Home tab, click Position and pick a Distribute option.

Contents

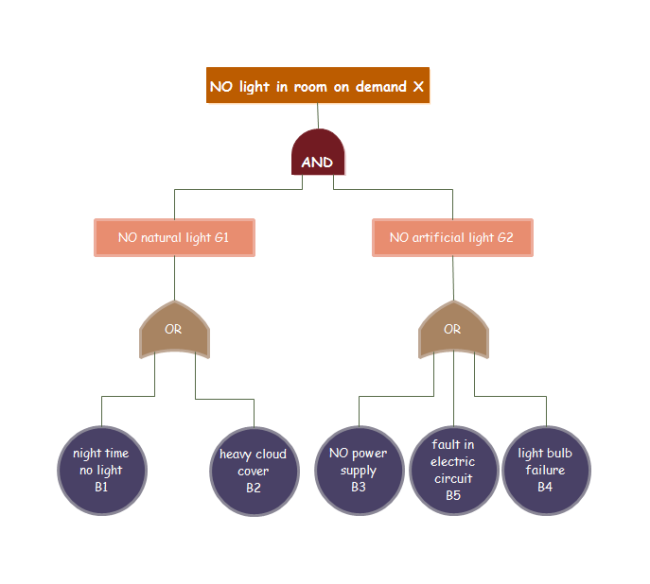

What is a Fault Tree Analysis (FTA) - Definition

The fault tree analysis is a deductive process. Developers or engineers use it to find out the root cause or human errors for different types of software, engineering facilities or hardware. It usually starts at a single point (the undesired top-level event) and then goes downwards in the form of a tree (the top-down structure) with a number of blocks and symbols to show the relationship between events (mechanical components). More specifically, the definition of 'Fault' in fault tree analysis indicates the occurrence of an undesired state for a component or system. For example, the light is failed off due to the switch failure as shown below (click on it to see more details).

Furthermore, the term 'Fault' has the following three key types:

- Primary Fault - A component failure that cannot be further defined at a lower level of a system;

- Secondary Fault - A component failure that can be further defined at a lower level, but with limited details;

- Command Fault - A state that is commanded by an upstream failure.

History of Fault Tree Analysis

The development of fault tree analysis has the following main stages:

- The Early Years - In 1961, Bell Labs developed the model for the use of Air Force Minuteman Launch Control System. Later, Boeing company use the fault tree analysis model for the design and evaluation of both civil aircraft and commercial aircraft. Around the 1970s, engineers in the aerospace and nuclear power industries further adopted the fault tree analysis model for complex projects.

- The Middle Years - Fault tree theory became popular among different countries with the adoption of technical algorithms and codes. Around the 1990s, the software industry and the chemical sector also introduced fault tree analysis.

- The Recent Years - Worldwide professionalists developed more commercial codes for the use of reliability engineering and robotics projects. Now, fault tree analysis is regarded as one of the most significant system reliability and safety analysis tools.

Here is a fault tree analysis example for finding out the cause of aircraft crash. Feel free to click on it to see more information.

Why Use Fault Tree Analysis?

Overall, it offers a well-structured, highly visual and comprehensive picture of your system. It helps users or developers quickly understand the results based on the logical relationships in order to pinpoint drawbacks and errors in the design process. Some other important benefits are:

- Easy to Adopt - Administrators can easily make changes for their system, evaluate for possible effects, design quality test and maintain procedures according to their fault tree analysis diagrams.

- Wide Applicability - Many subjects and fields use fault tree analysis, such as organizations in hardware, software, algebra, probability, reliability, physics, chemistry and engineering sectors etc.

- Risk Estimation - Engineers or developers can identify risks prior to a program launch by using the fault tree analysis model.

- For Complex System - It can be used to monitor and manage the safety performance of large-scale complex systems, for example, the fuel and aircraft project.

Fault Tree Analysis and other Analytical Models

Developers often compare the fault tree analysis, the Failure Mode Effects Analysis (FMEA) and the Reliability Block Diagram (RBD):

Relationship with FMEA

- Fault tree analysis is in the form of a top-down tree, while FMEA usually has a matrix structure with all the key measurements (severity rating, occurrence rating, process controls, detection rating and risk priority number etc.) right on the top column.

- Fault tree analysis can be used to show single or multiple initiating faults, but it could be hard to find all possible faults by using fault tree analysis. In contrast, FMEA does well in exhaustively cataloging initiating faults and identify effects, but not good at exploring multiple or single faults.

- In some cases, FTA and FMEA can be used at the same time for a better system development (e.g. the analysis of civil aerospace).

Relationship with RBD

- RBD depicts a system by using paths rather than gates in fault tree analysis diagrams.

- RBD focuses on the success part while fault tree analysis works on the failure part.

- Fault tree analysis is normally used for analyzing fixed probabilities of the occurrence of each event. RBDs may cover time-varying factors during the analysis process.

Fault Tree Analysis Diagram Symbols

Fault tree analysis has three basic symbol types: events and gates symbols.

Events

This sub-category includes the following shapes:

- Primary/basic event is normally shown as a circle. It is a failure or error in a system component or element.

- External event is normally shown as a house-shape. It is an event that normally expected to occur.

- Undeveloped event usually means some component in a system that needs no more investigation due to limited information.

- Conditioning event is a restriction on a logic gate.

- Intermediate event is usually placed above a primary event in order to show more event description details.

Gates

These symbols mainly show the relationship between output and input events, and the two most popular ones in this sub-category are OR gate and AND gate.

- OR gate - It occurs as long as at least one of the input events occurs.

- AND gate - It occurs only if all input (at least two) requirements are met.

- Exclusive OR gate - It occurs only if one of the input conditions is met, not if all conditions are met.

- Priority AND gate - It occurs only after a specific order of conditions.

- Inhibit gate - It only occurs if all input events take place and whatever is defined in a conditional event.

More Fault Tree Analysis Diagram Symbols

Here you can see more fault tree analysis diagram standard symbols including the transfer type and the line type etc.

How to Undertake a Fault Tree Analysis?

Although the nature of the undesired event may be quite different, fault tree analysis has the same procedure for any types of undesired event. To do a comprehensive fault tree analysis, simply follow the process below:

1. Define and identify the fault condition (hazard) as precisely as possible based on the aspects such as the amount, duration, and related impacts etc.

2. Using technical skills and existing facility details to list and decide all the possible reasons for the failure occurrence.

3. Break down the tree from the top level according to the relationship between different components until you work down to the potential root cause. The structure of your fault tree analysis diagram should be based on the top, middle (subsystems), and the bottom (basic events, component failures) levels.

4. If your analysis involves the quantitative part, evaluate the probability of occurrence for each of the components and calculate the statistical probabilities for the whole tree.

5. Double-check your overall fault tree analysis diagram and implement modifications to the process if necessary.

Fault Tree Analysis Template Word

6. Collect data, evaluate your results in full details by using risk management, qualitative and quantitative analysis to improve your system.

What else Should You Consider When Doing Fault Tree Analysis?

If you want to efficiently undertake or improve your fault tree analysis process or diagram, just have a try for the following tips:

- Leave more space for further tree expansions or possible changes in your fault tree analysis diagram.

- Make sure that your top undesired event is reasonable. In this case, you can test potential results against the original problem, or do peer review to make an adjustment.

- Use correct symbols according to their specific meanings.

- Offer a detailed description of your event text and avoid general words such as 'failure' or 'fault' when explaining your component problem.

- Your analysis team should include the system design engineer, the reliability engineer and the system data analyst with an engineering background for the study of your system.

- One fault tree diagram can only be used to apply for one undesired event analysis.

- Label your causes in different color codes to easily identify risk levels: red for critical risk, orange or yellow for high risk, and green for low risk etc.

More Free Fault Tree Analysis Templates

The best way to learn fault trees analysis model is to check out some easy fault tree templates. Free feel to click on any of these fault tree templates below to see more details or download them for free.

| Motor Fail FTA Diagram | Tank Explosion FTA Diagram | Quenching Burn FTA Diagram |

| Mine FTA Diagram | Power Signal FTA Diagram | Scaffolding Fall FTA Diagram |

How to Create a Fault Tree Analysis Diagram?

Creating a fault tree analysis diagram is easier than you think. Just do the following steps:

Fault Tree Analysis Template Excel

Step 1: Open a Blank Page

Run the fault tree analysis diagram software, go to Business Diagram, then double-click the Fault Tree Analysis icon to open a blank drawing page. Alternatively, you can directly click a built-in template to start your work.

Step 2: Add Shapes

Drag and drop the fault tree analysis standard symbols on the drawing page, and edit them in suitable sizes to fit your tree structure. You can also explore the built-in library to switch to other kinds of fault tree analysis diagram shapes.

Fault Tree Analysis Template Excel

Step 3: Connect Shapes

Select proper connectors to connect shapes. Also feel free to add more connection points on your shapes.

Step 4: Add Text

Open a text block to add details or just double click shapes to add directly. You can also insert supportive materials such us hyperlinks or notes for your shapes.

Step 5: Further Customize Your Shapes

Now you can do a series of formatting for your fault tree analysis diagram, for example, choose a new theme from the built-in themes, change the diagram background, customize the text color and align shapes by clicking the relevant menus.

Step 6: Save, Print and Export Your Work

Click Save on File tab to save as the default format. Choose Saveas on File tab to save as other formats. You can also choose to save in local files or save in the Edraw personal or team Cloud. Hit Export & Send to export your work to many different formats including PowerPoint, JPG, PDF and so on.

FTA Diagram Software Recommendation

Don't know where to start? Simply try the intelligent Edraw Max for drawing your fault tree analysis diagrams on Windows, Mac and Linux. Feel free to use the pre-made fault tree diagram standard symbols and templates based on the drag-and-drop editor and the straightforward user interface. You can also personalize your fault tree analysis diagram by changing the sizes and colors, replace the text with yours to gain a visually appealing diagram. Have a try right now by clicking on the free download button at the end of this page!